Edogawa Craft Stories

【Cleaning Brushes】A 109-Year-Old Heritage Carrying Forward Craftsmanship That Supports Food Safety

In a residential neighborhood in Chuo, Edogawa City, Tokyo, there is a cleaning-tools manufacturer with a 109-year history. Founded in 1916 in Nagoya, Aichi Prefecture, TAKASAGO Corporation (originally Horii Shokai) moved its base to Edogawa in the early Showa era and has continued manufacturing here for more than 90 years. Today, with professional cleaning brushes for food factories as its mainstay, the company offers some 900 products combining nine types of bristles and 32 shapes. We visited the production site that supports food safety with dependable quality—brushes that “won’t shed” and “won’t chip.”

From Household to Professional Use: A Path Chosen with an Eye on the Times

The company Horii Shokai, predecessor of TAKASAGO, was founded in the Taisho era. Plastic did not yet exist, and, according to fourth-generation president and representative director Yoshida Noriyasu, the company made household cleaning tools such as brooms and tawashi (scrubbing brushes) mainly from natural materials.

“Our flagship products at the time were the Takasago Broom, which used fibers from fern plants, and the Shojiki Tawashi, which used palm fibers. We entered the Tokyo market in 1934. To develop new markets, Horii Shokai opened a Tokyo branch office in Higashi-Komatsugawa, Edogawa City, and the person dispatched there was my grandfather, Yoshida Shinji, who later became our second president. A few years after that, my father—the third generation—was born.”

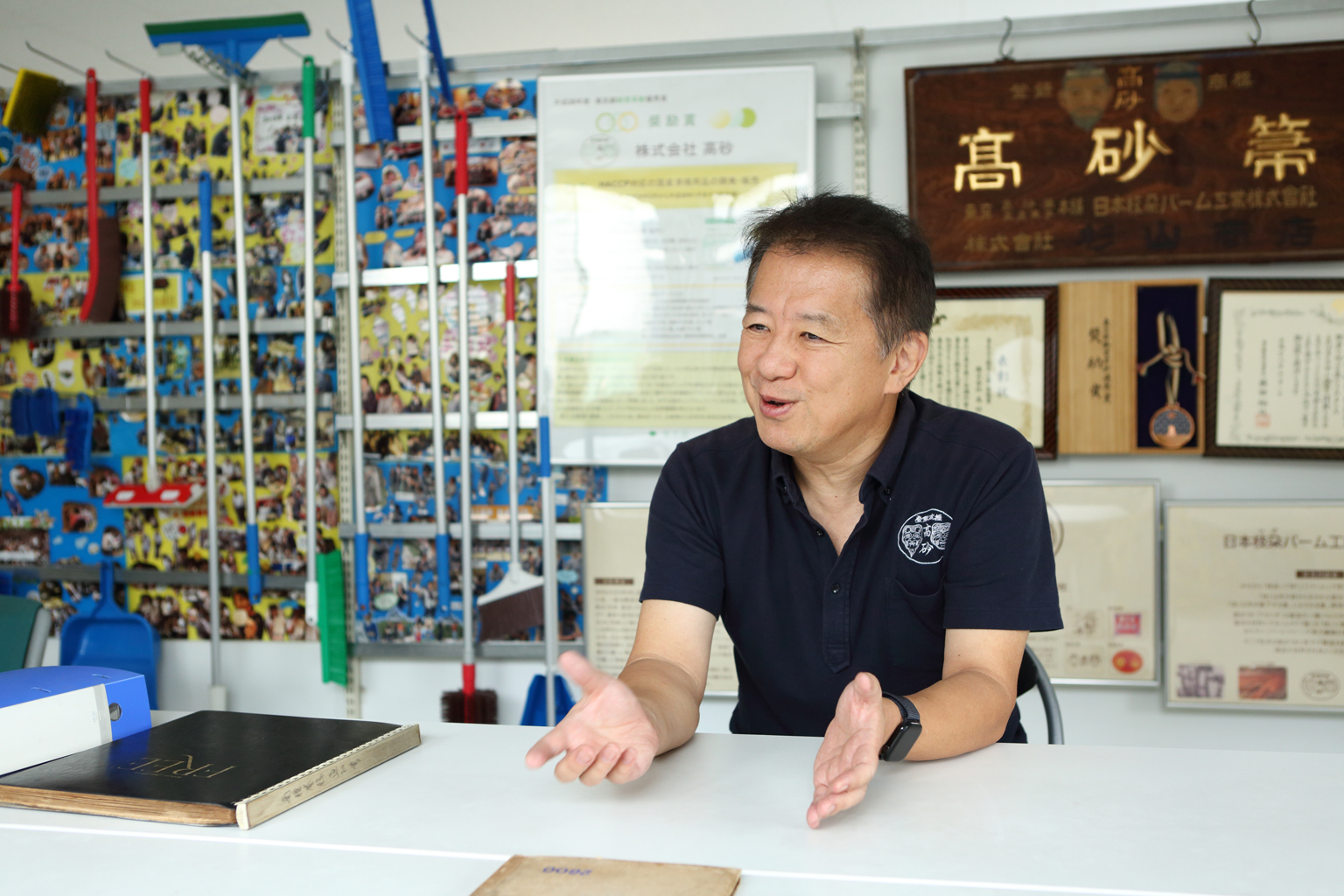

Yoshida Noriyasu, TAKASAGO’s fourth-generation president, speaking about the circumstances of the company’s founding. Behind him is a signboard that conveys the history of the company’s own broom trademark, “Takasago Hoki,” from which the company name derives.

A photograph preserved in old materials shows products made at the time of the founding. Even during the wartime period, when supplies were scarce, they managed allocations and manufactured garden brooms and tawashi using palm fibers.

Following steady business growth, the company moved in 1947 to Chuo, Edogawa City, where its headquarters still stand today. Three years later, it was incorporated as Nihon Shida Palm Industry Co., Ltd., and, in step with changing lifestyles, expanded its lineup of cleaning tools such as mops and brushes.

From the 1970s onward, the rise of home-improvement centers fueled business growth, and sales exceeded one billion yen. But in the 2000s, the environment surrounding domestic manufacturers changed dramatically.

“When I joined the company in the 1990s, home-improvement centers were increasing across Japan and sales were growing, but price competition was intensifying as well. In the 2000s, more manufacturers began producing in factories in China, and cheaper products flooded the market. Our clients also began seeking lower prices, and before we knew it, we were carrying enormous inventories. We were forced to confront the reality that the cheap, mass-produced model would no longer work.”

The turning point came in 2004. After launching the company’s first website, a major food manufacturer inquired: “The cleaning brushes we currently use in our factory are large and heavy and difficult to handle. Isn’t there a better Japanese-made option?” Investigation revealed that many food factories in Japan were using European-made cleaning brushes. This was the encounter with the professional brush market.

“Sensing an opportunity to develop a new market, we exhibited professional cleaning brushes at a trade show for food-service products in 2007. The result, however, was a complete failure. Because we used the same materials as for household products, we received a complaint that ‘After just three days, the bristles had set into a bend and the brushes were unusable.’ Professional and household markets are completely different worlds; professional use requires even more durable materials that can withstand repeated daily use. In the end, we had to discard roughly two tons of materials we had procured for the new professional brushes. I still haven’t forgotten how frustrating that was. It made me determined that next time we would make the real thing.”

Betting the Company on New Equipment from Europe

In 2010, when Yoshida Noriyasu became the fourth president, an internal reform began. The first step was changing the company name from Nihon Shida Palm Industry to TAKASAGO in 2013.

“When we started online sales, we kept getting questions like, ‘How do you read the character in your company name?’ or ‘I can’t type those characters.’ So we decided to unify under ‘Takasago,’ a brand name already familiar in cleaning tools.”

The TAKASAGO trademark, designed in the early Taisho era. Derived from Zeami’s Noh chant “Takasago,” it has long been considered auspicious, symbolizing longevity and marital harmony.

Next came a review of the production setup that had relied on external plants, and a move to strengthen in-house manufacturing for professional brushes. As a statement of that resolve, Yoshida says he “took the plunge like jumping off a cliff” and introduced a European bristle-insertion machine that plants each tuft of bristles into the brush base.

“By reinforcing in-house production, even if a defect occurs, we can understand the mechanism, refine the shape, and deliver products built to a deeper quality. For us it was a huge investment—truly a bet-the-company decision. And then the machine broke after just two weeks.”

At first they suspected a defect in the machine, but exchanges with the manufacturer revealed the cause. Unlike Japanese industrial machines that produce stable quality when run strictly by procedure, European machines assume a professional operator. They require fine adjustments for conditions like climate, humidity, and materials—in other words, it was a ‘machine from a craftsman’s country.’

“We learned the hard way that buying an expensive machine doesn’t magically produce great products. But the employee in charge refused to give up, kept working with this difficult machine, and gradually mastered its operation.”

In the food industry, which underpins demand for professional brushes, there is a conservative bent: unless there’s trouble like foreign-matter contamination, tools are seldom switched out. Even after shifting to in-house production, it took TAKASAGO a full three years to earn food factories’ trust.

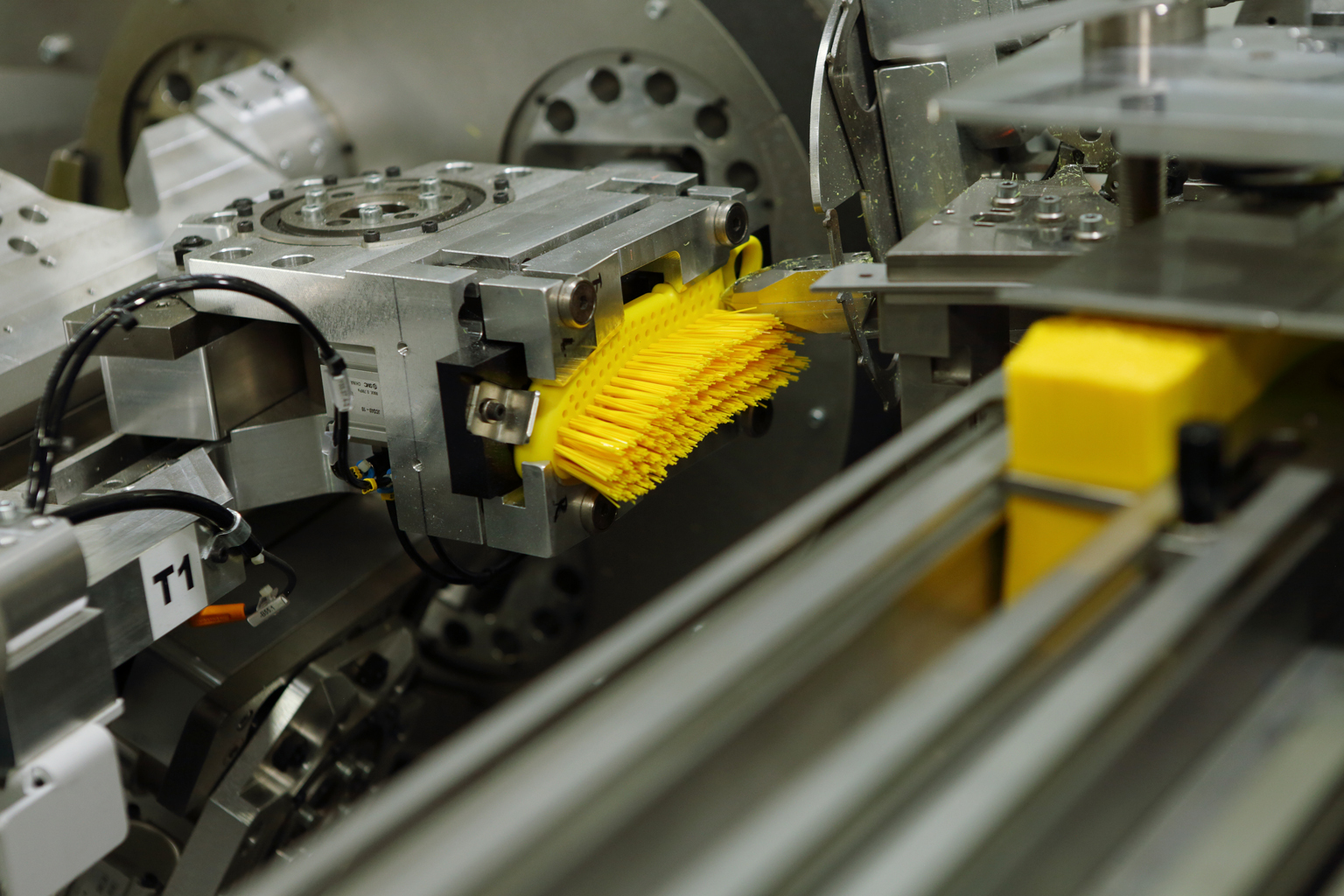

Professional brushes in vivid colors—designed so that if a base ever breaks or a bristle sheds and gets into food, it can be spotted immediately.

“Of course, new entries face high hurdles. For example, in a food plant making boxed lunches for a convenience-store chain, a single shed bristle mixed into a product could trigger a recall on the scale of 10,000 stores. These companies operate with the awareness that failing to maintain quality can threaten their very survival. That’s why, as more of them gradually chose our brushes, we felt tremendous joy.”

Orders eventually surged to the point that running the bristle-insertion machine from morning to night still couldn’t keep up. Today four machines are in operation. With 32 shapes and 9 bristle materials combined to meet HACCP requirements, the company has built a system capable of producing some 900 brush types.

A proprietary, professional-grade bristle material. The special fiber’s cross-section is triangular, making it easier to lift and remove soil.

Through steady effort unafraid of change, TAKASAGO’s brushes have earned trust for quality that “doesn’t shed” and “doesn’t chip.”

Quality That “Doesn’t Shed” and “Doesn’t Chip,” Created by Machines and Craftspeople as One

We observed the actual production process. Stepping into the factory, we heard the steady rhythm of machinery. Even while working, employees and part-time staff noticed visitors, paused, and greeted us warmly—an impression that stood out.

The flagship products made here are the HP/HPM Series brushes, designed to strengthen HACCP and foreign-matter contamination countermeasures. Sized to suit Japanese users with a lightweight body and cleaning power delivered by a proprietary bristle material, they offer high durability for two hours a day over three months of use.

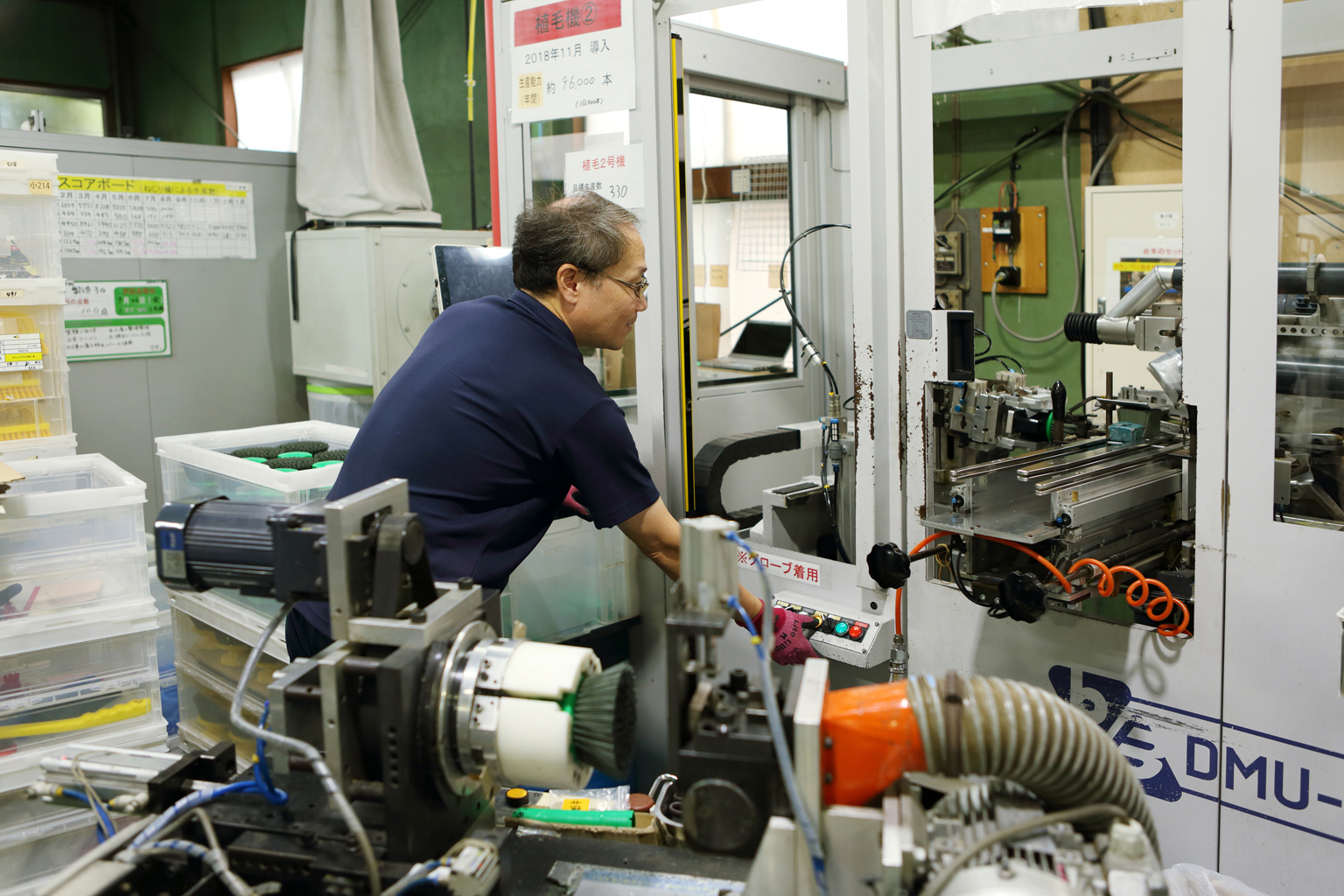

The first bristle-insertion machine that President Yoshida said he purchased “with the resolve of jumping off a cliff.” The employee who honed their skills through trial and error with this machine oversees production while making fine adjustments.

A production operator stands beside each machine, making fine operational adjustments in light of subtle lot-to-lot differences in materials and environmental conditions such as temperature and humidity. This integrated technique, with machine and person working as one, underpins TAKASAGO’s high quality.

Drill holes are made in the brush base for bristle insertion. The machine then plants the correct amount of bristle firmly into each hole.

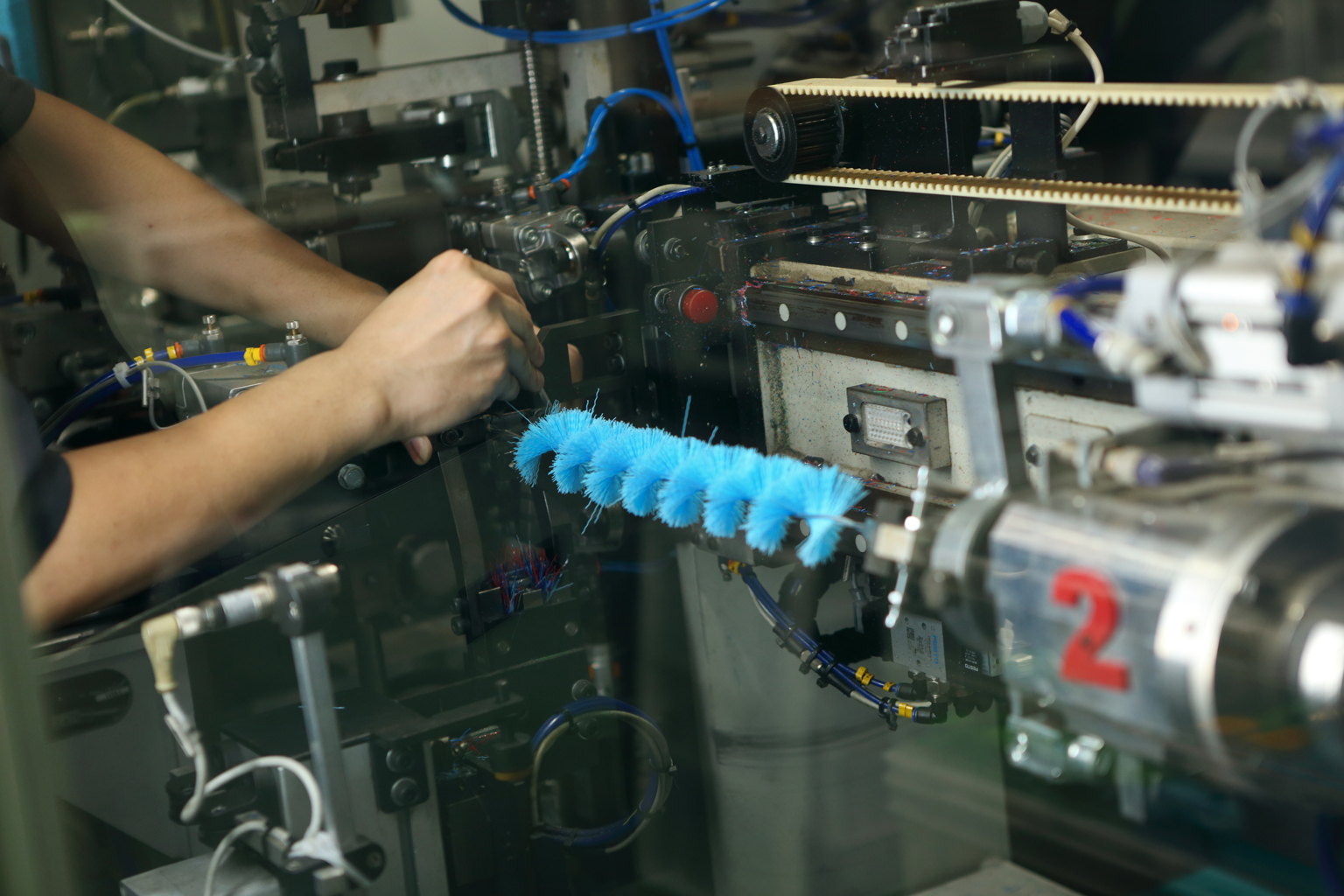

For tawashi and pipe brushes, a twisted-wire bristling method is used. Bristles are wrapped by twisting wire, formed into a helix, and then trimmed to a uniform length.

“After bristle insertion, we move to the ‘shearing’ step. If the brush surface isn’t even, cleaning performance is affected. Even with an automatic shearing machine, it takes finesse to finish stiff bristles to a uniform length.”

Shearing the bristle surface. Human adjustment is also needed when making products with curved forms.

Inspection of finished products is another task where you can’t let your guard down. If any fragment of bristle material adheres, it can cause foreign-matter contamination in food. While each stage—bristle insertion and shearing—includes thorough air-blowing, items are checked once again during post-inspection packaging before being shipped to clients.

Products are carefully re-checked by eye and packed while confirming that no residue has adhered.

One product that particularly embodies TAKASAGO’s commitment is the HP Hand Brush L, used for tasks such as cleaning professional cutting boards. Based on a household tile-cleaning brush for baths, it’s a signature item refined down to the details.

“To make it easy to grip, we curved the base and added grooves along the sides to reduce slippage. We also thickened just the tip of the base and shortened the bristle length there. That creates extra stiffness at the tip, making it easier to remove soil. Because many plants hang tools for hygiene control, we enlarged the area where a hook can catch.”

TAKASAGO offers a HACCP-compliant lineup tailored to many cleaning applications. (From left) HP Hand Brush L (yellow), with a tapered tip to scrape into corners; HP Hand Brush M (red), whose base narrows at the center for an easy grip; and HP Hand Brush Round (green), shaped to let you apply force with the palm.

The vivid five-color lineup signals HACCP compliance. Colors allow instant recognition—“for vegetables,” “for meat,” and so on—enabling zone management that prevents cross-contamination.

“Recently, more on-site staff at food factories come from overseas. Even if language doesn’t get across, HACCP’s color coding conveys the intended use. We’ll keep listening to our customers’ needs and expand safe, reliable, easy-to-use products.”

Striving to Be “No. 1 in a Small Field,” Hand in Hand with Edogawa City

More than 90 years have passed since TAKASAGO made Edogawa City its base of craftsmanship. The relationship with the community hasn’t always been smooth, President Noriyasu Yoshida recalls.

“In the past, I think we were probably a real nuisance to nearby residents. The more orders we had, the more trucks we sent out. Company vehicles narrowed the streets, and at rush hour we’d sometimes get honked at. Our larger parking area has solved that problem now, but a company that people don’t want around isn’t acceptable. That’s why we still do a neighborhood cleanup once a month.”

“As a company that manufactures cleaning tools, we have a duty to give back by keeping our neighborhood clean,” says President Yoshida about his feelings toward Edogawa City.

Edogawa City is also President Yoshida’s hometown. What does he find appealing about it?

“My wife says it’s easy to live here—the area is good for raising kids and has strong medical services. Maybe because people gather here, many of our part-time employees are exceptionally capable, juggling housework, childcare, and work. For me, they’re Edogawa City’s greatest appeal. We’ll keep offering flexible shifts so they can go home if a child comes down with a fever—and I hope they’ll continue supporting TAKASAGO’s production capacity.”

The Management Plan Book, distributed to all employees every year for 18 years since 2007. Reading the plan aloud together every morning builds shared principles that make the organization strong.

The company president’s conviction is that people power sustains craftsmanship. At TAKASAGO, all employees—including part-time staff—share daily reports in a “kaizen (improvement) proposals” system where frank comments about difficult aspects of the job are openly exchanged. Listening to voices from the floor and continually improving the work environment feeds directly into TAKASAGO’s strength in making.

A new initiative also began during the 2020 COVID-19 pandemic: the launch of CRASOU, a cleaning-tool brand for general consumers.

CRASOU’s concept is “cleaning tools you’d be happy to receive as a gift.” The line offers premium brushes that pair TAKASAGO’s hallmark quality with refined design, now available at major general stores and large online retailers.

“Our challenge is to deliver the know-how we’ve built in professional brushes to everyday consumers. Now that we’ve earned a certain reputation in the food-factory sector, we want a B2C pillar alongside B2B. I hope it becomes a stepping-stone toward the next hundred years.”

President Yoshida says he has long aimed to become “the best in Japan in a small field.”

“It’s not a bad thing to set big goals like expanding overseas, but our first target is to be No. 1 in market share within the field of Japanese food factories. What matters is that our employees feel proud to work at TAKASAGO. To that end, we are going to pursue being ‘No. 1 in Japan’ in our niche.”

A CRASOU series nail brush. The handle uses recycled plastic—gentle on hands and on the planet. Also available at the Edogawa Collection online store.

Rooted in Edogawa City, TAKASAGO protects food safety and supports clean, comfortable living. The founding spirit that began with the Takasago Broom and Shojiki Tawashi lives on today—unchanged for over a century—in honest quality that “doesn’t shed” and “doesn’t chip.”

Writing: Kiuchi AkI

Photos: Takeshita Akiko

Introduction of the Artisan

Founded in 1916 in Nagoya, Aichi Prefecture, as Horii Shokai, a maker of tawashi (scrubbing brushes) and garden brooms, the company expanded into Edogawa City, Tokyo, in 1934 and has manufactured cleaning tools there ever since. In 2010, the company was renamed TAKASAGO. Under fourth-generation president Noriyasu Yoshida, the company now focuses on cleaning tools centered on professional brushes for food factories. Since 2020, it has also developed the consumer brand CRASOU.

・TAKASAGO Corporation

・2-2-3 Chuo, Edogawa City, Tokyo